|

The 208 ToolBox and BOB expander

FAQ

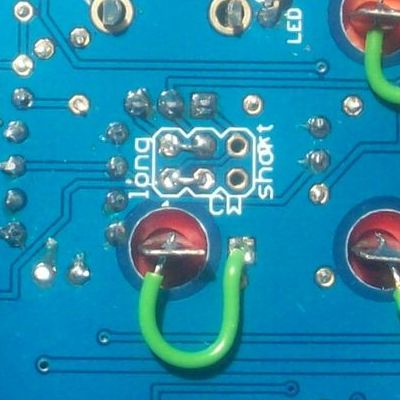

User Did you carefully read the user manual ? Some features may be different from what you think. Does the ToolBox / BOB Expander work with my Roman's 208r rev1 ? No Does the ToolBox / BOB Expander work with my Roman's 208r rev2 or 208r rev2.1 ? Yes Does the ToolBox / BOB Expander work with my BEMI/BUSA Music Easel, Easel K , LEM-208 , 208C ? Yes Does the ToolBox / BOB Expander work with my Portabellabz 208p ? Yes My ToolBox or BOB doesn't want to insert into the Easel card slot. Some recent BEMI Music Easels seem to have a card slot slightly shorter than standard and come with tapered program cards. Sand gently the ToolBox's or BOB's male connector will ease insertion. Pay attention to sand equally both edges to keep the male and female contacts aligned. Should I turn my Easel or 208 off before plugging or unplugging the ToolBox or BOB expander ? Yes What's the power draw of the ToolBox and BOB ? ToolBox with oscillator (741) option : 18mA +15V / 15mA -15V BOB with slew limiter (TL072) option : 5mA +15V / 5mA -15V Some features such as the envelope looper or sequencer outs don't work. Ensure the "control" switch next to the 208's edge connector is well in its central position ("both"). The ToolBox is active despite the "control" switch is set to "front panel" or "local". This is normal behaviour, even with the control switch set to "front panel" or "local" most features remain active. The envelope on the ToolBox doesn't work. Where is its output ? You should read the user manual. The envelope doesn't start looping when I switch the looper to self. The envelope needs an initial pulse, like the pulser. If switched when off, it won't loop. Switch while on or trig it with a pulse. The sequencer 5th stage pulse out outputs a constant signal instead of a pulse. Your BEMI / Buchla USA 208e or 208c is in cause, not the ToolBox. A footnote in the 208c Addendum for the manual says : "In “Meta-Programming” for the original program card, all five stages are mentioned as solder-able--programmable in value --with a resistor. But since Rev5 of the 208 (and often modified in Rev4), the Sequencer 5 stage has been replaced by a local enable signal by default in order to signal to the card when the control switch is in “both” mode. This never affected iProgramCard users. This only affects users who program the sequencers with resistors using the original Program Cards. For those who would rather get that signal back, it is assumed they are already familiar with soldering. On the 208C program card PCB they can cut the trace (below “E”) between the square via and "ENLOC” and solder a wire from that square via to SQ5B1. It can be restored by returning the connection with a wire between that square pin and ENLOC. Note however that in both historic manual examples, stage 5 is left open/unconnected anyway". The sequencer ALL and 12345 outputs don't work with other gear or modules. These outputs are not buffered and their output voltage drops to 3.5V when patched. It is ok for use in the 208 but for use with external gear, optional buffers should be installed to prevent the voltage drop. External CV/gate signals don't work. Ensure the 208 and external device grounds are well interconnected via a jack socket or the ground banana socket. Can I use the BOB expander standalone ? Yes Can I connect the ToolBox horizontally to the BOB expander ? Yes but you should support it from below. Can I safely connect other gear to the 208 via the ToolBox or BOB expander ? Yes but check the max voltages the other gear accepts. The ToolBox can output voltages up to +/-15V. Do the edge connectors need cleaning ? How can I clean them ? If bad contacts occur, the edge connectors are probably dirty. Rub the ToolBox's or BOB expander's male connector on both faces with a cloth and Isopropyl Alcohol (IPA). Fold a thin cloth wet with IPA onto the male connector of a program card and gently plug it a few times into the 208's connector to clean the female contacts. Is there a risk to damage my other Buchla modules using the ToolBox or BOB expander ? Although 100% safe with any 208, the 218e and any other 200e modules could be damaged if you send an audio signal or a negative CV to a CV or pulse input banana. The ToolBox's CV mixer and BOB expander's envelope inverter are able to output negative CV therefore do not patch these to a 200e module. A schottky diode added in series with the 218e or other 200e module's input bananas is a straightforward easy to DIY protection from accidental negative CV / audio patching. Is there a risk to damage the 208's edge connector using the ToolBox or BOB expander ? The 208's female edge connector is solid and as long as it's not heavily forced it's ok. Hold the ToolBox or BOB expander with hand when plugging or unplugging a patch cable relieves pressure on the edge connector. I've been using similar patchable cards for years and it's still perfect on my own Easel. No related issue was reported to my knowledge, being with the ToolBox or iProgram card or other. If an accident occurs, it's easy to replace, no special DIY skills or tools are needed and I can supply with a direct drop-in replacement. My ToolBox suddenly caused the Easel or 208 to stop working. I'm very sorry about this. Some 100nF (104) ceramic caps used in a few pre-built units proved faulty and fried after a variable time of use, causing a short between the +15V and -15V power rails. These are the coupling caps next to the TL072 and TL074 ICs , visible from the sides, one is located between the "5" banana socket and "att." slider, the other next to the mixer LED. Most caps of this batch are ok but unfortunately the risk exists for units shipped around July and maybe August 2017. If this occurs with your ToolBox or if you want to replace the suspect caps preventively, please contact me and I'll help you do it yourself or we'll arrange a return to have it fixed by me. Of course I'll pay shipping costs. Don't worry about your Easel or 208, no one was damaged by this problem. Builder Did you carefully read the build notes ? Do they match your PCB revision ? Did you carefully read the user manual ? Some features may be different from what you think. Some parts seem missing in my kit or I have another problem with my kit. Please contact the kits seller (SAmodular or SynthCube). The kits are not my business and I don't check their content, so are beyond my control and I'm not able to help. Can I purchase a kit or parts directly from Portabellabz ? No. Only PCBs sets or pre-built units are available from me. What is the large white rectangle silkscreened on the back with 3 arrows and 3 x 3 pads for ? This is meant to host a littleBits module and should be ignored otherwise, nothing else is meant to be mounted there. What are the +15V, 0V, -15V pads for ? These pads are directly connected to the power rails and meant to power extra circuit built on the perfboard. Those should NOT be connected to anything else neither shorted.  The envelope looper doesn't work. Check you well placed the jumpers or bridges for the pot course as described in the build notes. If the LED is always on, replace the 2N3904 next to the CD4093. A builder reported that a CD4093BCN didn't work in this circuit and switch it to a CD4093BE fixed the problem. A feature doesn't work. Double check your build for a missing part, a bad solder joint, a solder bridge shorting 2 pads etc... A possible cause is a short with 0V (ground plane). Do a continuity test with 0V on the banana eyelet and edge connector pad. Most traces are banana eyelet > resistor > edge connector and easy to follow. Contact me if a drawing of the signal trace is needed. When the ToolBox is plugged in my Easel stops working. There's likely a short between power rails and/or 0V (ground plane). Remove the ICs from their socket and perform a continuity test between the +15V, 0V and -15V pads. If there's a short, you can locate it by cutting the rail trace at different points and do a continuity test after each cut. You can repair the cuts afterwards by bridging with a cable. I don't seem able to debug myself. Depending on the quality of your build, I could accept to fix it at cost if it's shipped to me. Contact me. |